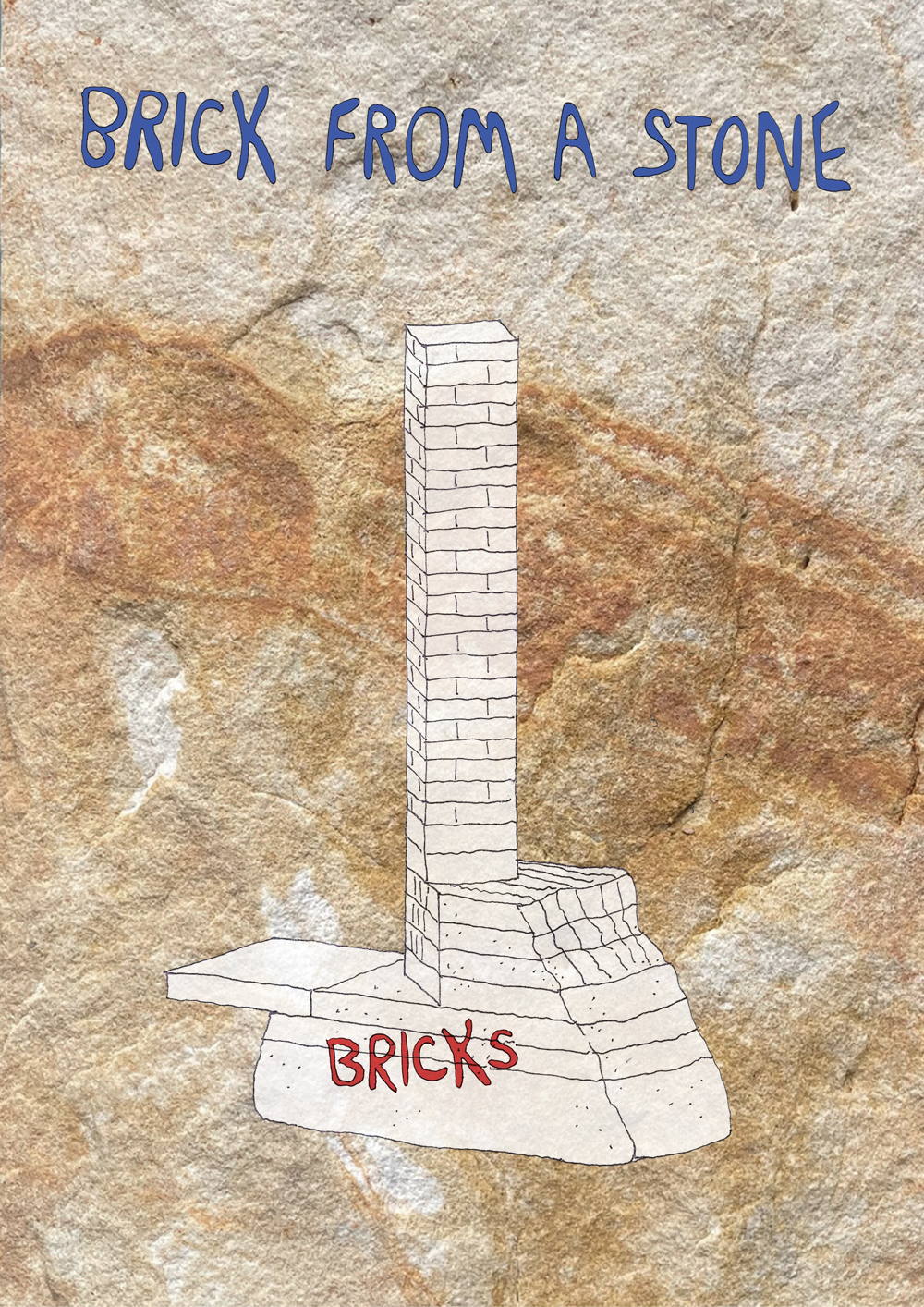

“Brick from a Stone” maquette exhibited at The Summer Exhibition, The Royal Academy of Arts

18 June - 18 August 2024

June 12, 2024

Above photo credit: Ivan Jones

A maquette for Brick from a Stone, an installation that appeared at Clerkenwell Design Week 2024 in May, has been selected for the Architecture rooms at The Summer Exhibition at the Royal Academy of Arts.

British stone suppliers Albion Stone and Hutton Stone commissioned London-based architecture practice Artefact to design Brick from a Stone to demonstrate the low impact manufacturing journey stone takes to be turned into a brick. Both companies have invested in state-of-the-art machinery to turn ‘unloved stone’ (blocks/slabs of limestone and sandstone with superficial inconsistencies) into new collections of stone bricks.

The 3-metre-tall Brick from a Stone installation at Clerkenwell Design Week showcased the huge potential stone bricks have as a beautiful low-carbon building material. Consisting of just under 900 stone bricks, its embodied carbon was less than a quarter of what it would have been if it had been built from traditional clay-fired bricks.

The installation was such as success that Artefact worked closely with Hutton Stone to produce a 1:3 maquette of one of the columns sculpted from a boulder of Darney Sandstone from its quarry in North Northumberland. The maquette was then submitted to Assemble RA, the committee that has curated the Architecture rooms for the world-famous Summer Exhibition this year. Assemble RA specified that it “welcomed submissions that focus on and reflect on making as a process.”

Above - ILLUSTRATION BY ARTEFACT; PHOTO CREDIT: IVAN JONES

“We’re thrilled that our maquette of Brick from a Stone has been selected for such a prestigious exhibition,” said Benedetta Rogers, Director of Artefact. “It celebrates the traditional skills and new technologies used today to carve in stone and embraces all the imperfections that come from a natural material.”

“The piece hints at the potential to create a new low-carbon vernacular for masonry buildings in the UK” added fellow Director, Daniel Marmot.

“The Royal Academy of Arts has given us a chance to showcase the craftsmanship of stone masonry which has declined since the wide adoption of concrete ushered in by Modernism,” explained Marcus Paine, managing director of Hutton Stone. “The maquette also shows how we’re turning our ever-growing surplus of so-called imperfect stone into a low-carbon construction material. Any waste is unacceptable in the current climate crisis, so fundamentally this is the right thing to do.”

In early 2018, Hutton Stone supplied the Royal Academy with Darney Sandstone for internal paving and skirting for alterations and restoration.

“As reducing embodied carbon in buildings becomes a priority, we expect architects to be drawn to the sustainability credentials of these stone bricks,” added Michael Poultney, managing director of Albion Stone. “We’re now set up to produce a million stone bricks a year. This is just the start.”

For further press information or high-resolution images:

Belinda Fisher, Friends & Co: +44 (0) 7808 721 308, belinda@friendsandco.co.uk

Notes to editors:

THE CARBON FOOTPRINT OF THE BUILT ENVIRONMENT

According to the World Green Building Council, the building and construction sector is responsible for almost 40% of global, energy-related carbon emissions - 28% from operational emissions (heating, cooling, lighting etc) and 11% from ‘embodied carbon’ (extraction, manufacture and transportation of materials and construction).

The UK has many different types of stone, but when measured as a building material, its embodied carbon is significantly less than manufactured materials like concrete and clay-fired bricks. Even in their ‘greenest format’, concrete bricks are a high carbon building material. Clay-fired bricks don’t include cement, but the clay they are made from needs to be milled, water added and mixed or extruded, moulded, dried, and baked in a kiln.Stone starts as zero carbon as it doesn’t need to be manufactured - the only energy required is to extract it from the ground, cut it into blocks and cut it again into bricks. The final product has a low factor of embodied carbon. When local stone is used for local construction projects, the carbon footprint associated with transportation is negligible.

Albion Stone’s Heritage Portland Stone Bricks have a carbon footprint of 8.4kg CO2e per m2 (0.14 kg CO2 per brick). Hutton Stone’s Darney Heritage Natural Stone Bricks have a carbon footprint of only 11.4kg CO2e per m2 (0.19 CO2 per brick). These figures are from Verified EPDs. The UK manufactures almost 2 billion traditional clay-fired bricks a year – their carbon footprint is estimated at 42.6kg CO2e per m21, the equivalent of five Heritage Portland Stone Bricks or around 3 ½ Darney Heritage Natural Stone Bricks.

ABOUT THE SUMMER EXHIBITION AT THE ROYAL ACADEMY OF ARTS

One of the founding principles of the Royal Academy of Arts was to “mount an annual exhibition open to all artists of distinguished merit” to finance the training of young artists in the Royal Academy Schools. The Summer Exhibition is the world’s largest open submission contemporary art show which has taken place every year without interruption since 1769. It provides a unique platform for emerging and established artists to showcase their works to an international audience, comprising a range of media from painting and printmaking to photography, sculpture, architecture and film.

The Royal Academy presents its 256th Summer Exhibition in 2024. The Architecture rooms were curated by Assemble RA, a multi-disciplinary collective working across architecture, design and art. Founded in 2010 to undertake a single self-built project, Assemble has since delivered a diverse and award-winning body of work, while retaining a democratic and cooperative working method that enables built, social and research-based work at a variety of scales, both making things and making things happen. www.royalacademy.org.uk

ABOUT ARTEFACT

Artefact is a London-based architecture studio, founded by Benedetta Rogers and Daniel Marmot. They seek to enact positive societal change in their work, designing uplifting buildings and spaces that reflect the culture of their users. From homes to installations to community buildings, each Artefact project has a distinctive identity that stems from the background of their clients and the wider community, the atmosphere of the site and leaps of the imagination.

Their work is focussed on the craft of architecture, with a commitment to detail, grounded in the reality of how things are constructed. They use everyday materials in unexpected ways and explore new materials that reduce the environmental impact of what we build. artefact-studio.com

ABOUT HUTTON STONE

Hutton Stone’s highly skilled and friendly team of 44 staff are dedicated to supplying the finest quality, natural and sustainable UK sandstone. With Production Facilities in the Scottish Borders and North Northumberland they supply throughout Scotland and across the UK.

Founded in 1994 by Managing Director Marcus Paine, a 5th Generation Quarrier and Past President of The Stone Federation GB, the company operates three exclusive sandstone quarries with state-of-the-art sawing and production equipment and also stocks a further 20 other types of British stone to serve their wide client base. Hutton Stone specialises in new build and restoration supply projects with highly skilled banker masons, carvers, and mass-produced walling production too. In 2024, as part of a focus on a sustainable future for natural stone it launched Darney Heritage Natural Stone Bricks, a new sustainable construction product with a quarter of the carbon footprint of clay-fired bricks. www.huttonstone.co.uk

ABOUT ALBION STONE

Albion Stone is a family run company that has been supplying Portland stone for projects in London for almost a century and quarrying Portland stone for nearly 50 years. When Michael Poultney became Managing Director in 1991, he relocated the factory to Portland alongside the quarries and, to secure more reserves for the future, switched from quarrying to the more environmentally sensitive mining. The company has expanded to be a major stone mining operation that is one of the largest and most technically advanced stone factories in the country.

Albion Stone produces some of the most environmentally sensitive building products in the world, and this year launched its new Heritage Portland Stone Bricks which can reduce the embodied carbon of external walls by up to 75% when compared to clay-fired bricks. www.albionstone.com

1 Figures calculated from the MPA Mortar; Learning Text Part 05 https://mortar.org.uk/documents/LT05-Bricks-and-Blocks.pdf and also from the Brick Development Association EPD. Calculations based on a solid clay brick with no frog for a more accurate representation.